Products

JIWMS

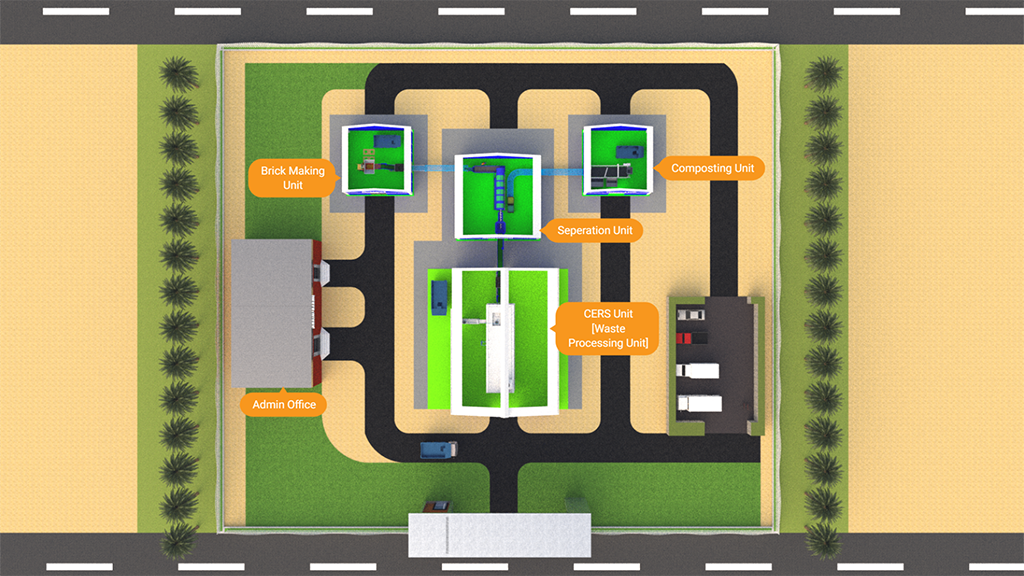

JERS INTEGRATED WASTE MANAGEMENT SOLUTION

The integrated solid waste management approach includes systems for minimizing, collecting, composting, recycling and disposing of waste. JERS provides a convenient solution for all types of nontoxic solid waste streams. Generated compost, electricity, oil, reusable materials will pay for managing the waste and eventually eliminate the need for landfill sites altogether. . The ecosystem can also utilize existing landfill sites as a fuel source to free up space for other purposes. In this way, the valuable materials contained in the existing waste can be recycled for re-use inorder to preserve the virgin raw materials.

Societies generate several other types of waste streams on top of the municipal solid waste. Hazardous waste, such as hospital and electronic waste, and liquid waste, such as wastewater and sludge, requires its own special treatment methods. JERS can incorporate all waste streams into one turnkey solution. Energy and recyclable materials are extracted from the waste and the remaining materials are made inert and safe. JERS’s internal synergies make one plus one equal more than two.

JIWMS

UNSEGREGATED MUNICIPAL SOLID WASTE RECYCLING SOLUTION

Our Municipal waste management service offers a real alternative to landfills, whereby we recover valuable energy from materials that cannot be recycled and is being wasted presently. Some of most valuable resources recovered from this technology are listed below,

- COMPOSTING

- CARBONIZATION

- FUEL RECOVERY

- PLASTIC RECYCLING

- GLASS RECYCLING

- WASTE TO ENERGY

- BIO-FERTILIZERS

- TEXTILE-FIBRE RECYCLING

- METAL RECOVERY

JERS - CANKYO RECYCLING SYSTEM [CRS]

RAPID FERMENTATION AND DRYING SYSTEM

The CRS is a rapid fermentation and drying system utilizing a cost effective environmentally friendly thermal process with integrated heating coils that can transform any homogenous organic waste material into value-added products, such as Bio-organic fertilizer or animal feed, in less than two hours.

The basic technology of the CRS involves reproducing the natural circulation system in the machine for a short period of time. Organic wastes such as, food processing waste, sludge etc., are fed into the reactor, which would then be vacuumed to maintain a certain optimal temperature for decomposing. As a consequence, ideal conditions for rapid composting is provided within the bioreactor and the output is dehydrated within a short time

APPLICATIONS

- Slaughterhouse Waste Treatment

- Fish Waste treatment

- Poultry waste treatment

- Oil extraction

- Sludge recycling

- Plants/trees recycling

- Oil Refinery Waste treatment

- Industrial wastewater treatment

KEY FACTS

- Technology Used: Microbial Fermentation & Drying

- Process : Rapid Fermentation and Drying with heavy metals treatment.

- Capacity Available: 0.5T-25T

- High Speed Process : 2 hours per batch

- No odor, No water effluents. No Pre-Process

- No Boiler,No Vacuum,Easy Operation, Low Maintenance

- Suitable for indoor use.

JERS - PLASMA AMP

BIO-MEDICAL WASTE TREATMENT SYSTEM

PLASMA AMP is a revolutionary Non-Combustion system which uses the Plasma Technology to reduce the volume of waste to 4 % ash in 1 – 2 hours without using any external power source and is Smoke Free.

Flue gas that is emitted from the heating chamber after the destruction complies with the US EPA Std guidelines on Waste Incineration specification limit.On the other hand, the chamber temperature is regenerated to dry the input wastes by increasing the volume of waste destruction.

KEY FACTS

- Technology used: Plasma Pyrolysis

- Capacity Available: 0.5T-50T

- Waste reduced to 4% concentrated ash.

- No segregation required

- Pollution free-complies to the US EPA Standards

- No fuel required, hazardous waste reduction

- No toxic fumes, small footprint

- Stand alone, unmanned, optimized degradation

- No smoke & odor

APPLICATIONS

- Medical Wastes

- Electronic Waste

- Residential and Commercial Buildings

- Landfills

- Airports and Ports

- Urban Areas

- Schools,Parks, Shopping Malls

- Urban Areas

JERS - RENDERING MACHINE

POULTRY WASTE PROCESSING UNIT

JERS Rendering systems turn animal by-products that are not intended for human consumption into valuable end-products:animal feed compounds, fats and oils

with the highest protein and digestibility levels. To use animal by-products in other processes they have to be treated first. The way of processing determines the value of the end-products.The working principle of rendering machines involves a combination of heat, pressure, and mechanical action. The raw materials are first ground and then cooked at high temperatures to separate the fats, proteins, and other valuable components from the waste.

APPLICATIONS

Animal Feed Production

The machine grinds and cooks the raw materials, producing a nutrient-rich meal that can be used to supplement livestock feed.

Fertilizer Production

The machine processes the waste, producing a nutrient-rich Bio-organic fertilizer that can be used in agriculture.

Biodiesel Production

While the machine processes fat, it separates glycerin and turns the remaining oil into biodiesel fuel.

Industrial Applications

The machine can process chicken fat into fatty acids, which can be used in a variety of applications for the production of soap and other personal care products.

KEY FACTS

- Waste reduction, Promotes Sustainablity

- Helps food recovery hierarchy by recycling animal by-products

- Converts animal by-products into high quality end-products

- Recovered resources have high economic value

- Increases energy self-sufficiency

- Helps reduce greenhouse gases

- Reduces the need for landfills

- Safe and Healthy animal feed as by-product

- Reduces the need for landfills

J-GLASS

GLASS RECYCLING PLANT

J-GLASS is a glass waste recycling facility that produces a lightweight porous pumice-shaped foam with 99% of the glass waste produced by a community as a raw material.

The lightweight foam porous artificial material (pumice stone) is produced by grinding, baking and spent glass foam.

It can be used for a wide range of purposes, including greening, insulation, horticulture, purification, construction, civil engineering, etc.,and is a high value-added product playing a vital role in the formation of the recycling society.

APPLICATIONS

- Light weight embankment material

- Backfill material of retaining wall

- Earth pressure reduction material for underground structure

- Drainage ground material for athletic field

- Culvert drainage material

- Inorganic soil improving material

- Hydroculture

- Water purification material

KEY FACTS

- To make “Foamed Glass” , unlike in most other recycling processes, the base material doesn't need to be cleaned or treated-in any way.

- Labels can still be affixed, and the bottles don't need to be sorted by color. The glass is loaded into a receptacle, crushed, then ground into a powder.

- The powder is then mixed with a proprietary formula of natural additives and baked.

- The mixture foams and swells about fourfold, meaning better returns from the base powder product than in most other recycling processes.

JERS - OIL SLUDGE

OIL SLUDGE SEPERATION SYSTEM

APPLICATIONS

Sludge is semi-solid slurry that causes environmental disruption. Presence of Sludge causes environment to become anaerobic. It causes hydrogen sulphine gas which is deadly for human beings. Sludge draws out oxygen from water bodies above thereby lowering DO levels which can cause fish kills. Sludge also stores pathogens which affects public health. Sludge is a mixture of organic waste and sediments. It spreads across the body of water, further towards the centre. In many lakes and drains, the cornice can be deeper than the water.

However, dumping and concealing dredging sludge can cause environmental problems. How to Use and Dispose of Sludge Silt is a critical problem that countries need to pay special attention to. Our JERS Oil Sludge separation system technology can avoid environmental pollution from sludge; and use rejections to achieve social benefits. JERS Oil Sludge separation system utilizes superheated steam to achieve high temperature – oxygen free state inside the reactor to enable recovery of fuel oil from resin-based mixed waste c/w food residue, mud etc. It enables to reduce CO2 emissions, whilst reducing waste volume

- Oil Extraction

- Oil Sludge Recycling

- Oil Refinery Waste Treatment

KEY FACTS

- Achievement of oil recovery that do not include heavy metal

- Achievement of residue oil ratio would be 1~0.01%

- Consecutive treatment and operation

- Environment friendly device

- Only steam is used as a processing energy

- Chemicals and biological treatment are not used

JERS - ZERO E-BRICKS

WASTE TO BRICK PROCESSING UNIT

JERS Provided “JERS ZERO-E BRICKS” – an patented Japanese technology.

JERS ZERO-E Bricks are made from waste materials which and in turn contribute in conservation of non-renewable resources, improvements in public health and safety with environmental matters and reduction in waste disposal costs.

Waste to brick processing involves the conversion of various types of waste materials, such as fly ash, bottom ash, sludge, and industrial waste, into building materials, such as bricks, blocks, and tiles.

KEY FACTS

- Environmental Benefits

- Cost Savings

- Improved Quality

- Energy Efficiency

- Regulatory Compliance

APPLICATIONS

- Construction Material

- Landscaping

- Infrastructure

- Agriculture

- Art and design

JERS - CONTAINERISED COOLING SYSTEM

CONTAINERISED COOLING SYSTEM

JERS-Cooling is a fast cooling process for food at a temperature just below its freezing point. This process is done using specially designed JERS – Cooling containers that are capable of rapidly cooling food without freezing it.

JERS – Cooling containers use a combination of vacuum insulation, advanced cooling technology and accurate temperature monitoring.

JERS – Cooling containers are commonly used in commercial food storage and transportation applications, such as in the shipping of seafood, meat, and other perishable foods. They are also increasingly popular in kitchens, especially when it comes to preserving fresh fruits and vegetables and keeping leftovers fresh.

KEY FACTS

- Extended shelf life

- Reduced waste

- Improved food safety

- Improved food quality

APPLICATIONS

- Shipping and Logistics

- Retail and Supermarkets

- Food service and Catering

- Home use

JERS - DFS

JERS - DESERT FARMING

JERS Desert Farming technology introduced by the JERS Corporation is a type of agriculture method that involves cultivating crops in arid or semi-arid regions, where rainfall is limited and water resources are scarce. It is a challenging form of agriculture that has innovative techniques and technologies to overcome the harsh environmental conditions of desert regions.

Desertification is a major threat to biodiversity. JERS offers a solution to convert deserts into arable and green lands providing a long-term solution to world hunger and climate change.

Desert agriculture involves modern farming techniques for the cultivation of crops in arid areas which were previously considered unsuitable for agriculture. Desert agriculture relies on maximizing the availability of water. Much of the Middle East was not what we see now about 10,000 years ago. It was a place of rolling grasslands, forests and jungles receiving torrential rains as in tropical Southeast Asia. Water is the most central in the greening of the area. Modern technologies have tapped into ancient water sources which are now buried and fossil water is trapped in aquifers.

Desert lands in the Middle East lie on huge reserves of not only oil but also water.Technologies have been perfected to maximise the utility of water with less energy for efficient desert farming.

KEY FACTS

- According to the World ResourcesInstitute, in 2019, 12 of the 17 most water-stressed countries in the world are in the Middle East and North Africa (MENA) region.

- Water shortage which is prevalent all over the world is much more pronounced in this area which makes conventional farming not practical.

- Today Desert farming is receiving a much more impetus from the Governments of the region to improve food security reduce water consumption, and promote sustainable development in the region.

- The Governments in this region are investing heavily in public-private partnerships and collaborations for sustainable agricultural practices.

- Middle East & Africa desert farming market was valued at USD 63.06 million in 2021 and is predicted to grow at CAGR of 5.71% through 2028.

BENEFITS

- Increased food security: Desert farming can help to increase food security in regions where traditional agriculture is not possible due to water scarcity.

- Conservation of natural resources: Desert farming can help to conserve natural resources, such as water and soil, by promoting sustainable agricultural practices.

- Economic development: Desert farming can provide economic opportunities for communities living in desert regions, particularly through the production and sale of high-value crops.

- Adopting regenerative faming in arid desert region using modern technology not only helps heal the planet but also improve human health, since accommodating increased demands on agriculture with existing farming practices and short-term fixes could lead to further land degradation, increased gas emissions, and intensified competition for natural resources.

- One of the many benefits of Desert farming is the drastic shift in the bacterial communities in desert soil. Bacterial communities in agricultural soils had increased diversity and improved ecosystem function for plant health.

- Desert farms being proposed by JERS shall be biodynamic farms having a significantly better soil quality than conventionally farmed soils but comparable to the soil quality achieved by other organic methods, due to the microbial rich bio-organic fertilizer treatment which is responsible for nutrient and organic matter supply. JERS organic fertilizers are known for their extremely high bacterial diversity and are also specific.

- Desert farming increased soil biodiversity; wherein indigenous desert microorganisms fulfill important functions in desert agro-ecosystems: whereas certain strains in-turn gets enriched via plant roots from desert soil.

JERS - PF

JERS - PLANT FACTORY

JERS Plant Factory is highly profitable indoor type technology aiming for a stable and efficient food supply. It is a “fully artificial light type” plant factory that controls growing environments of plants and cultivates plants in fully closed environments that do not use sunlight. Based on environmental and growth monitoring, it is a cultivation facility that performs annual and planned production of various vegetable plants by performing advanced environmental control and growth prediction

In a plant factory using artificial light, plants are grown indoors using hydroponic cultivation (growing plant without soil) with light and nutrient solutions provided artificially. One of the main advantages of this method is that the plants are not affected by weather or other factors. This also allows for operation with small footprints, making it possible to produce crops in urban areas and other environments.

KEY FACTS

- Rapid population growth

- All-Weather andyear around

- Climate change and seasonal instability

- Increasing need for improved food safety

- The rise of emerging markets

- Chemical-free hydroponic vegetable production and expertise

- Building highly profitable hydroponic production networks at home and abroad

- The delivery of consistent and quality controlled vegetables

- Promoting safety through chemical-free vegetable supply

BENEFITS

- Speed of Growth: JERS System increases production volume by a perfectly and safe high speed of growth. This number is not for “from nursery to crop” but “from seed to crop”.

- Electricity Consumption of Artificial Lighting: Compared to other hydroponic system, electricity consumption is only 25% because of perfect harmonization of the cultivating system. This contributes to higher profitability.

- Harvesting Ratio: JERS System has a 95% quality harvest ratio compared to the 60% of other hydroponic systems.

- Multiple Layer Planting: The number of layers increase not

only the production volume but also efficiency of supplying water and CO2, stabilization of temperature, humidity and levels of CO2. - Nutrient Content: JERS System Vegetables are more nutritious than field cultivated varieties.

JERS - GREEN H2P

GREEN HYDROGEN PRODUCTION & POWER GENERARATION

The conventional incinerator has been the vehicle where organic waste is volumetrically reduced and buried in landfills. Increasingly, this has become an unpleasant social problem where everyone wants their rubbish to be disposed hygienically. Land available for landfill use is also drastically reduced as waste Land is converted for commercial use.

GENERAL DATA

- Electrical Generation Capacity Per Hour - Up to 0.6MW

- Green Hydrogen Production Per Day - Minimum 500KG

- Organic Waste Feed Input Per Hour - 12 dry Ton

- Feed Loading Type - Vacuum or Screw conveyor

- Feed Process - Batch / Discrete Continuous

- Type of Feed - Singular source

- Pretreatment - Yes, grinding or shredding to 1~3 mm size

- Discharge or Output - Inorganic powder

JERS - PROBIOTICS DIVISION

JERS - PROBIOTICS

JERS brings you various blends of Animal Probiotics catering to health and disease management for cattle, poultry, fish and other related veterinary segments.

With our unique and proprietary technology, we use selective microorganisms in combination with plant derivatives to develop unique probiotic mixtures to enhance productivity.

PRODUCT RANGE

CATTLE:

- Feed plus probiotic

- Bio calcium

- Mineral Mixtures

AQUACULTURE:

- Booster probiotic

- NH4Aqua

POULTRY:

- Feed plus probiotic

PETS:

- Feed plus probiotic

APPLICATIONS

- Conventional Farming

- Commercial farming

- Urban Farming

BENEFITS

- Contains target specific strains of beneficial microbial consortium with high cfu.

- Rich in carbohydrate, proteins, vitamins, minerals and essential nutrients.

- Contains specific plant extracts.

JERS - GEOTHERMAL ENERGY DIVISION

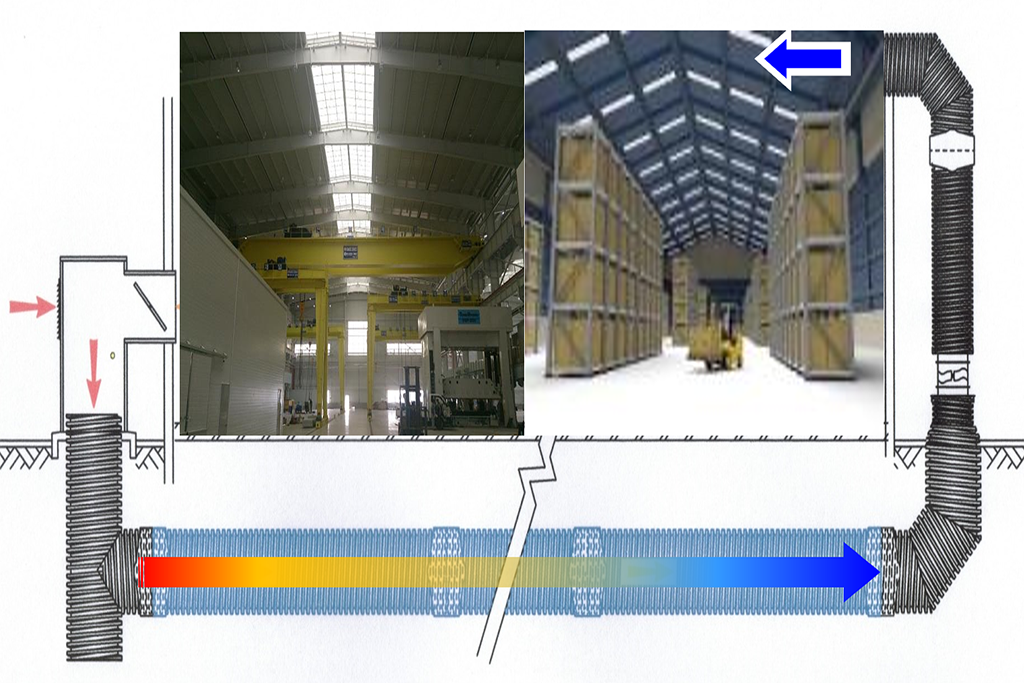

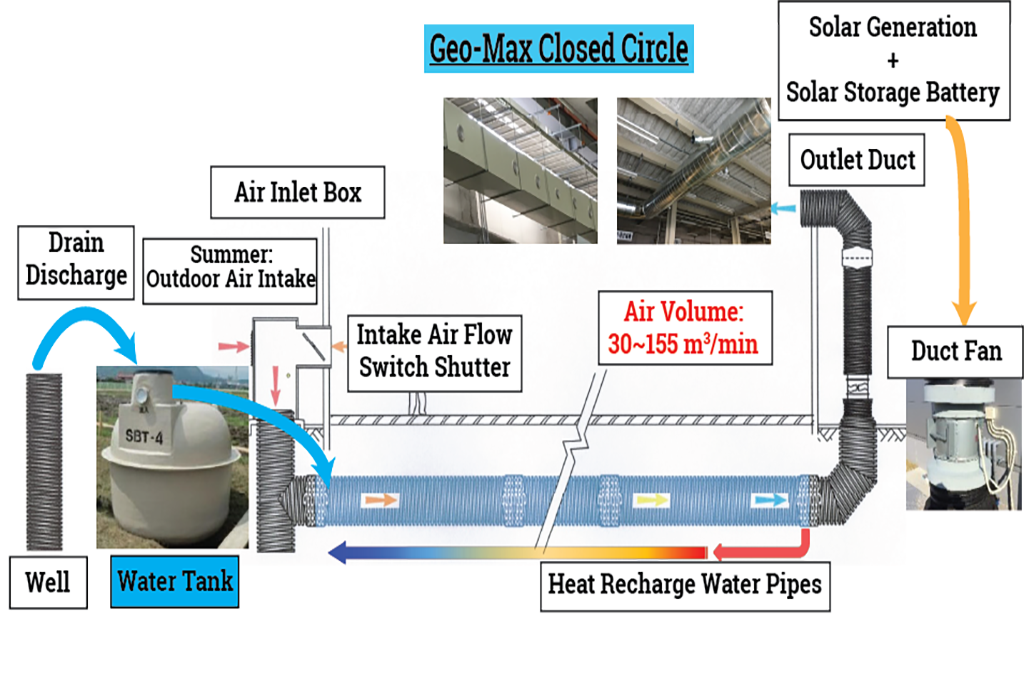

JERS - GEO-MAX SYSTEM

Geo-max system is a groundbreaking and environmentally friendly technology that utilizes geothermal energy from the Earth to provide efficient and environmentally friendly cooling for residential, commercial, and industrial buildings. It works by transferring heat between the building’s interior and the Earth’s subsurface.

With increased instances of unusual weather, people are more engaged to use renewable energies. In that, we, JERS Corporation has created a new geothermal energy air conditioning system called “Geo-MAX” which provides one of the largest air volumes among other geothermal air conditioning sources. It is most effective when employed in large-size architectures such as factories, gymnasiums, public facilities, housing complex, greenhouses and livestock shelters.

GEO-MAX SYSTEM OUTLINE

“GEO-MAX is One and Only System Using Geothermal Heat and Underground Water in the Most Effective Way”.

- The high density polyehtylene PE100, double-layered pipes are used for heat exchange [GA-800, GA600]

- The heat-exchange area is buried at a depth of 2 meters below the ground level (GL).

- Air Supply Volume is Variable by Fan Inverter

- The pipes are covered with hollow, spiral ribs for passing well water or hot water (depending on cooling/heating use),boosting heat-exchange efficiency

- If the circulating water is 15℃ and outside temperature is 35℃, it blows out approx. 26℃ air

- Capable of being installed in a multitude of places, with a primary requirement of available space.

- Low Electricity Consumption Running:0.33kw~1.45kw [Only Fan and Pump]

BENEFITS

- Energy Efficiency

- Environmentally Friendly

- Consistent Cooling

- Durablity & Longevity

- Dual-Functionality [Heating & Cooling]

- Suitable for Varoius Climatic Conditions

- Minimal Outdoor Equipments

APPLICATIONS

- Residential Buildings, Commerical Building, Schools and Educational Institutions

- Hospitals and Healthcare Facilities

- Industrial Facilities, Sports Facilities, Military Facilities, Greenhouses, Data Centres

- Hotels and Resorts, Muncipal Buildings, Historical Buildings.